Grease separators

A grease separator extracts animal or vegetable fats from the waste water. When installing a grease separator, there are a number of points of attention that are important to work properly.

On this page

- How to prevent fat, grease and oils in waste water

- How a grease separator works

- Installation and use of a grease separator

- Calculation size grease separator

- Maintenance

When preparing foods – such as baking and frying or frying in a restaurant’s kitchen – fat, oils and grease (FOG) is produced and is washed down with waste water. This waste water can not be discharged. The grease in the wastewater solidifies and settles in the sewer. This causes a reduced drain capacity of the sewer and can lead to blockage.

How to prevent fat, grease and oils in waste water

The waste water must not contain substances which may cause congestion of the sewer. For example, discharging leftover food into the sewer through a food grinder causes congestion . Animal or vegetable oils or fats must not enter the waste water. There is no need to get fat into the wastewater. A measure to keep fat out of the waste water is to always first remove the kitchen utensils and dishes of food residues prior to washing. The oil and grease residues which are removed can be disposed in the waste container. After that, less fat or oil is released when cleaning the dishes.

How a grease separator works

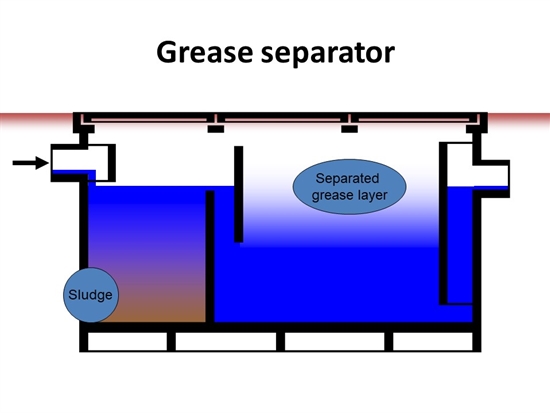

A grease separator or grease trap is a waste water treatment system. A separator extracts animal or vegetable oil and fat from the waste water before the waste water is discharged into the sewage system. This prevents the fat from spreading into the sewage and clogging. A grease separator works by using gravity. The light parts (fat and oil) in the waste water float on the heavier parts (food debris). The separation process takes some time. That is why the separator needs a certain size.

The waste water flowing into the grease separator is inhibited by the installation of baffle plates. The sedimentable material (food debris) drops down and the floating particles (fat) rise to the surface. The sludge and fat remain in the separator. The clean waste water can then flow to the sewer. In the image below, the operation of a grease separator is summarised.

Installation and use of a grease separator

Different grease separators may be used depending on the situation. The rules do not include to have one particular size, because the size may be too big for one company and for the other too small. With a limited amount of waste water, a small grease separator may be sufficient and can be installed under the sink. In professional kitchens, a larger grease separator is needed. It can be installed above ground. There are accounting rules to align separators to the business situation. When installing a grease separator, it is important to take into account:

- The grease separator is sized to mach the nature and scale of the activities

- The temperature of the waste water

- The amount of fat and sludge

- The use of cleaning agents

- Not to use a food grinder

For the purchase of a grease separator, it is important to determine the size of the grease separator. For proper functioning, it is important that grease has enough time to increase. Otherwise, the grease will go along with the wastewater and only solidify in the sewer. Also, the size determines whether wastewater has the time to cool down, so that fat comes up. There are calculation rules for calculating the size.

- The temperature of the waste water

When the temperature of wastewater remains high in the grease separator, grease remains in solution. It is not captured in the separator and only solidifies in the pump well or in the sewer. The place where the grease separator is placed in the waste water pipe and the size of the separator affect the temperature. A separator directly under the sink does not work well with high temperature waste water.

- Amount of grease and sludge

Sludge and grease are captured in the separator. This means that it also needs to be removed from time to time. Too much sludge and grease collected ensures that the separator does not work properly.

- The use of cleaning agents

Treat cleansers carefully. Grease is 'dissolved' in water by a cleaning agent. With the right remedy, this mixture in the separator breaks down again and the fat remains in the separator. With a wrong cleaning agent or in case of improper use, there is a chance that the mixture will not break up until after the grease separator. The grease then solidifies further into the sewer and leads to clogging.

- Not to use a food grinder

Do not place food grinders in the wastewater drain. This results in a large amount of settling waste and sludge, on which a fat separator is not calculated. You need to remove that sludge from the grease separator again.

Calculation rules grease separator

To the size of the grease separator, a calculation method can be used. See Capacity calculation fat separator based on type of kitchen.

Maintenance

As an indication that maintenance is required, the following values are used:

- maximum filling of the sludge collection space of 50 %

- maximum filling of the grease storage compartment (between the baffleplates) of 80 %.

This is a fat layer thickness of about 16 cm.

Record the maintenance in a logbook. This applies to maintenance on all installations. This data may be requested during an inspection.